Technology

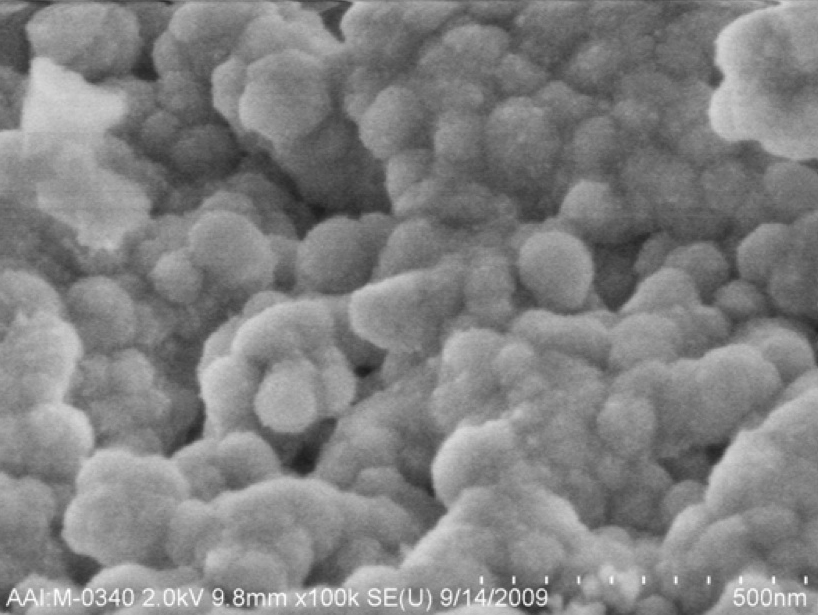

Nanoscale’s patented process is a metallothermic reduction, producing high-purity, low oxygen metals from anhydrous metal salts, and typically halides. Our process is a liquid-liquid/solid based process where liquid and solid metal salts are injected into a molten reducing metal.

SODIUM

Our standard reductant is sodium metal. However, we can use other reducing metals and alloys, including potassium, calcium, magnesium, aluminum and mixtures of these metals.

LIQUID

An important advantage of our process over other metal halide reductions is our patented use of a liquid/solid halide feed. This allows us to produce a wide range of homogeneous alloys and pure metals at a higher production rate than can be achieved with gas phase based reactors, and within a more compact footprint.

SEPARATION

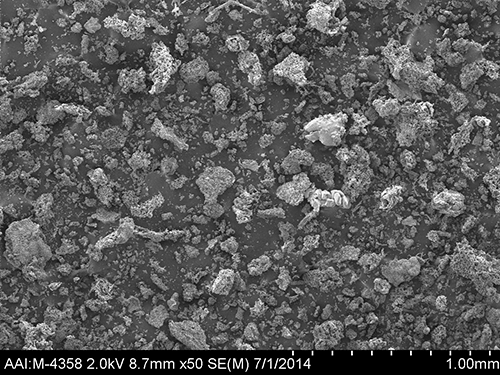

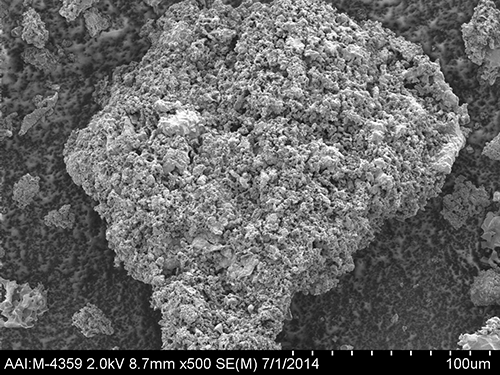

In addition to the high productivity reaction technology, Nanoscale has developed a proprietary process for the separation of the metal/alloy particles from the excess reducing metal.

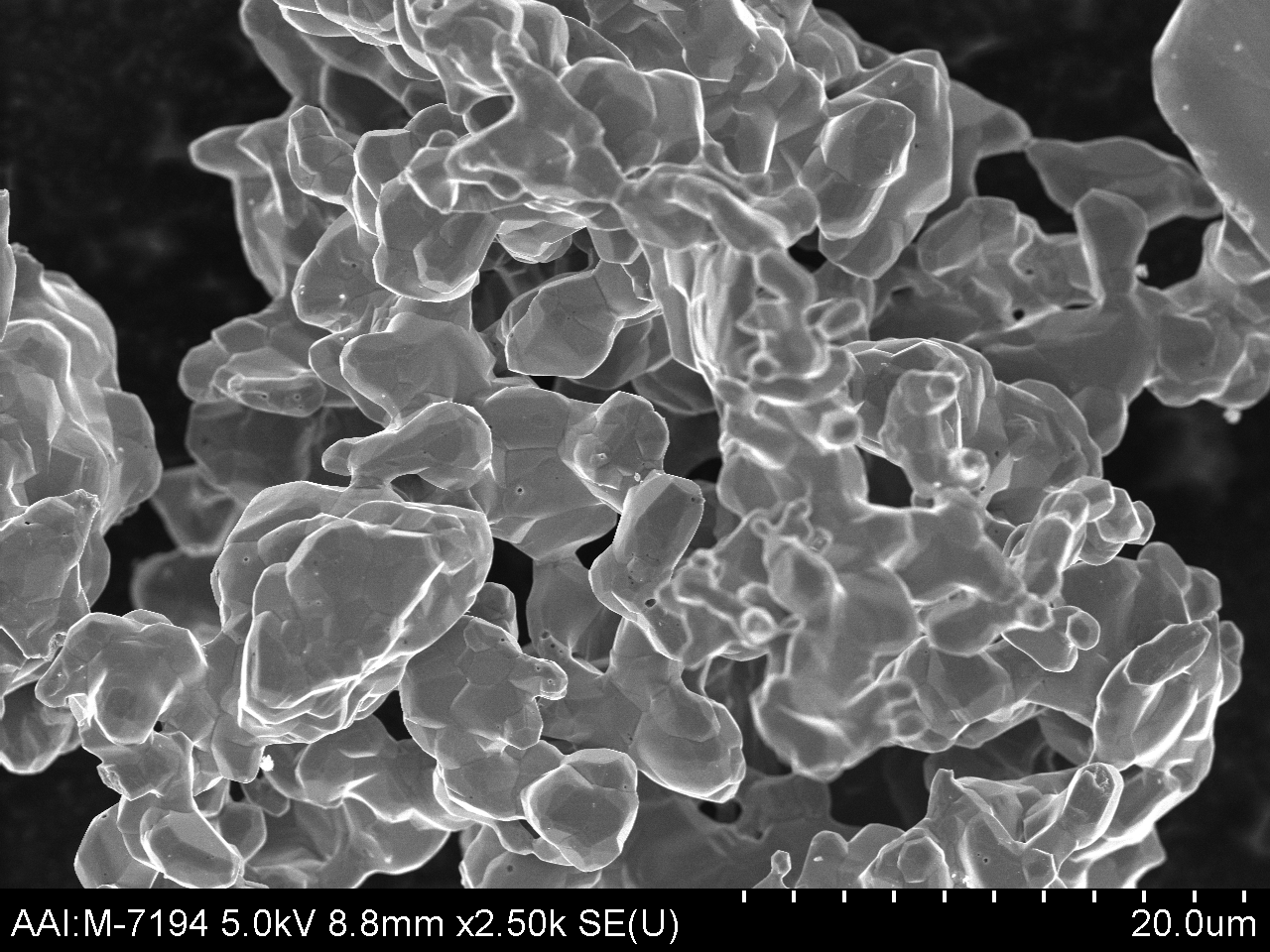

POWDERS

Today we are producing hafnium, titanium, and titanium alloys for powder metallurgy applications with powders for additive manufacturing under development.